If you have ever picked up a wedding invitation or business card and paused because it felt different in your hands, you were likely experiencing letterpress printing. I often get asked what is letterpress printing, and the simplest answer is that it is a traditional relief printing method where inked, raised surfaces are pressed directly into paper to create text or imagery you can both see and feel. That physical impression is not accidental. It is the result of pressure, paper, and a process that values craftsmanship over speed.

Letterpress was once the backbone of mass communication, used for everything from books to newspapers. While modern printing technologies eventually replaced it for high-volume work, letterpress has returned in a meaningful way.

Today, it is chosen deliberately for premium projects where texture, detail, and intention matter. That is why you now see it used for wedding invitations, luxury packaging, and high-end stationery rather than everyday print jobs.

What is letterpress printing in simple terms?

Letterpress printing works like an elevated stamp. A raised plate or type surface is coated with ink and then pressed into paper under controlled pressure. The ink transfers from the raised surface, and the paper receives both the color and, often, a physical impression.

This method belongs to relief printing, meaning the parts that print are raised above the non-printing areas. That simple mechanical principle is what gives letterpress its distinctive look and feel.

How does letterpress printing work today?

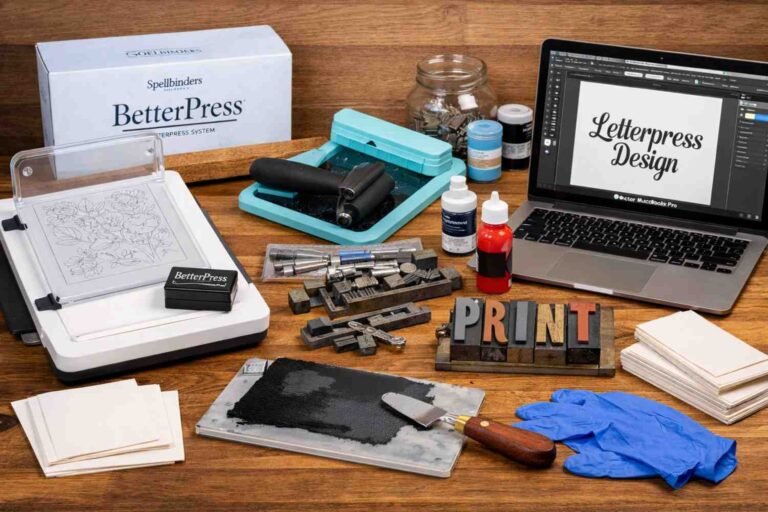

Modern letterpress blends traditional mechanics with contemporary tools. While the presses may look vintage, the workflow often starts digitally.

Composition: setting the design

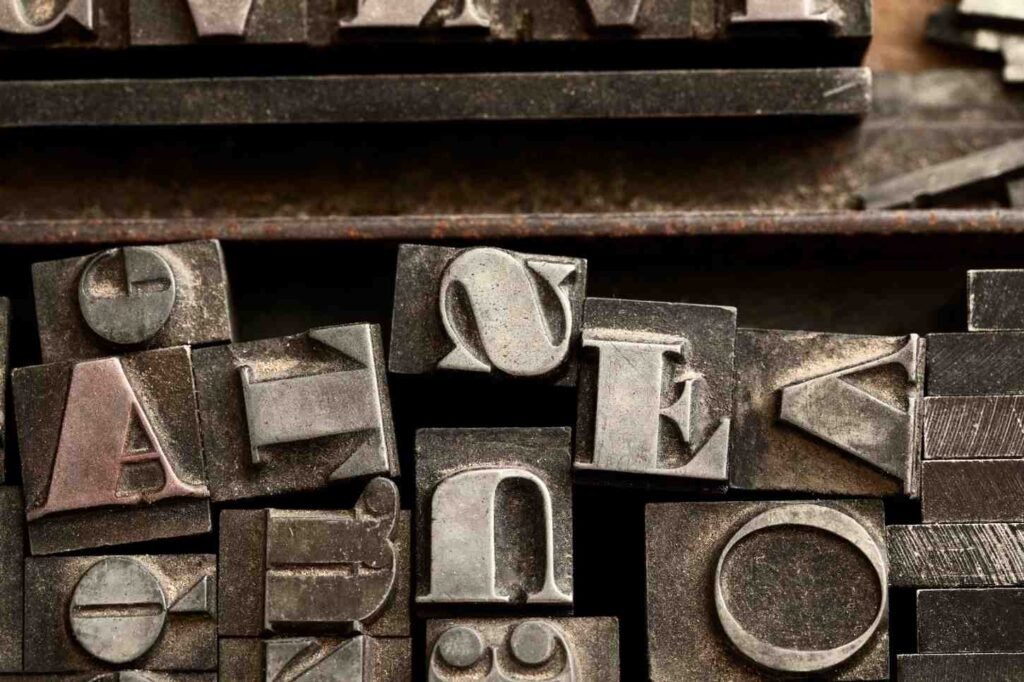

The design is prepared in one of two ways. Some printers use movable type, where individual metal or wood letters are arranged by hand. Others use photopolymer plates, which are custom-made from digital artwork and mounted to type height. Both methods create a raised printing surface.

Lock-up: securing the form

Once the type or plate is ready, it is secured into a metal frame called a chase. Spacing blocks known as furniture fill empty areas, while adjustable locking devices called quoins tighten everything into place. This lock-up process ensures nothing shifts during printing.

Inking and impression

Thick, viscous inks—typically oil-based or rubber-based—are applied to the raised surfaces using rollers. The paper is then pressed against the inked form with controlled force, transferring the image and creating the signature texture.

Separate passes for each color

Each ink color requires its own plate and a separate run through the press. This makes letterpress slower and more deliberate, but it also allows for exceptional control and precision.

Why does letterpress printing feel different from other methods?

Letterpress stands apart because it engages both sight and touch.

The tactile “bite” versus the historical “kiss”

Historically, printers aimed for a light “kiss” impression where ink transferred cleanly without denting the paper. Today’s aesthetic often favors a deeper debossed impression, commonly called a “bite,” where the design presses visibly into the paper.

Paper makes all the difference

Letterpress performs best on thick, soft stocks, especially 100 percent cotton paper. These papers can withstand pressure and showcase depth without cracking or distortion. Coated or thin papers reduce the tactile effect and are rarely ideal.

Intentional design over complexity

Bold typography, generous spacing, and simple shapes produce the best results. Letterpress rewards clarity and restraint more than intricate detail.

Letterpress vs embossing vs debossing: what’s the difference?

These techniques are often confused, but they serve different purposes.

Letterpress printing transfers ink from a raised surface and may create an impression.

Debossing presses a design into paper without ink.

Embossing raises a design from the back of the paper.

Some modern print pieces combine digital printing with debossing to mimic a letterpress look, but true letterpress always involves inked relief printing.

What types of presses are used for letterpress printing?

Most letterpress work today is produced on vintage presses that have been carefully restored.

Platen presses use a flat surface to press paper against the plate and are common for cards and invitations.

Cylinder and proof presses apply rolling pressure and are often used for specific layouts or artistic prints.

The press itself matters less than the skill of the printer and the care taken during setup.

Why is letterpress printing used for premium products?

Letterpress is no longer practical for mass production, but it excels in high-impact, small-batch work.

- Wedding invitations benefit from the romantic, tactile quality

- Business cards convey professionalism and brand confidence

- Art prints and posters emphasize craftsmanship

- Luxury packaging adds depth and distinction to labels and inserts

In each case, letterpress signals intention, quality, and attention to detail.

How to design for better letterpress results

Good letterpress starts with smart preparation.

Choose press-friendly artwork

Avoid ultra-thin lines and tiny reversed text. Strong shapes and readable typography hold ink better and print more consistently.

Decide on impression depth

Some printers prefer a subtle impression, while others lean into a deeper bite. Discuss this early, as it affects paper choice and press settings.

Plan colors carefully

Each color requires its own plate and pass through the press. Limiting color palettes often leads to stronger, cleaner results.

Frequently Asked Questions

1. Is letterpress printing the same as engraving?

No. Engraving prints from recessed lines, while letterpress prints from raised surfaces. The processes and tools are different, even though both create tactile results.

2. Does letterpress always leave an indentation?

Not always. Some printers aim for a light kiss impression, while others intentionally create a deeper debossed effect. The result depends on style and paper choice.

3. Why is letterpress printing more expensive?

Letterpress requires hands-on setup, careful lock-up, ink balancing, and often multiple press runs. The time and craftsmanship involved increase cost.

4. What products work best with letterpress printing?

Letterpress works best for invitations, stationery, business cards, art prints, and luxury packaging where texture and presentation matter.

Why letterpress printing still matters today

Letterpress printing is not about speed or scale. It is about presence.

In a world dominated by screens and disposable print, letterpress slows things down. It invites people to touch, notice, and engage. When used thoughtfully, it transforms simple text into something memorable, tactile, and enduring.

That is why letterpress printing continues to thrive—not as a relic of the past, but as a deliberate choice for meaningful design in 2026 and beyond.